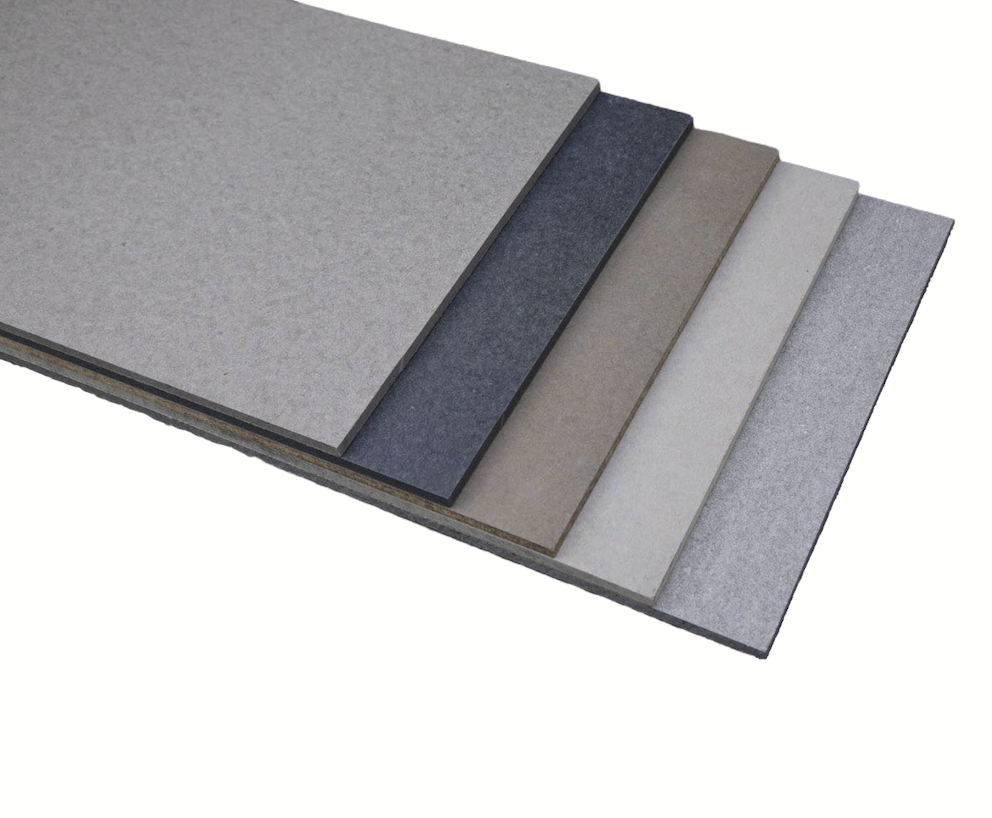

Calcium silicate board is a new type of environmental friendly building material, which has the functions of traditional gypsum board, as well as superior fireproof, moisture-proof performance and moisture-resistant, long service life advantages. It is widely used in ceiling, partition wall, building interior and exterior wall, home decoration, furniture lining board, billboard lining board, ship compartment board, warehouse shed board, network floor, tunnel, indoor engineering wall board and fluorocarbon paint stone paint deep processing. It is based on high-quality high-grade cement as the matrix material, and is reinforced with natural fiber. It is made by advanced production technology such as molding, pressing, high-temperature steaming and curing. It is a new type of building and industrial board with excellent performance. Its products are fireproof, moisture-proof, sound insulation, insect-resistant and durable. It is an ideal decorative board for ceiling and partition.

1. Excellent fire performance: Calcium silicate board is a class A non-combustible base material, suitable for interior decoration in places with fire restrictions, and can be burned without any effect. 2. Excellent water resistance: Calcium silicate board has excellent water resistance, and can maintain stable performance in high humidity places such as bathrooms and bathrooms, and will not expand or deform due to water absorption. 3. Excellent thermal insulation performance: Calcium silicate board has low thermal conductivity and good thermal insulation performance, which is significantly better than ordinary brick walls. It can be used as a thermal insulation integrated board and a lightweight partition board material. 4. High strength and light weight: Calcium silicate board has high strength, anti-bending, anti-bending, anti-impact, anti-sagging and other characteristics, and has a density of 1.4~1.5g/cm3, which is conducive to reducing building load. 5. Excellent sound insulation performance: Calcium silicate board has high surface hardness and good sound insulation performance, which can be used as sound-absorbing ceiling, ceiling, sound-absorbing wall, etc. 6. Excellent corrosion resistance: The coating of calcium silicate board can effectively prevent acid-base, pharmaceutical liquid erosion and extend service life. 7. Excellent cleaning performance: Calcium silicate board is stain-resistant, easy to clean, does not need to be plastered again, saving construction cost, material cost and construction period. 8. Excellent environmental performance: Calcium silicate board 100% does not contain asbestos, no radioactive elements, no benzene, no formaldehyde, belongs to a new type of green environmental protection building materials.

1、Installation process of calcium silicate board:

Snap line leveling → install hanger → install main keel → install secondary keel → install cross small keel → level and fix → install calcium silicate board.

2、Construction method and operation points of calcium silicate board: a. Snap line positioning: According to the design requirements, determine the ceiling elevation, and snap out the elevation line on the surrounding walls or columns. The edge keel should be snapped according to the design requirements and fixed on the surrounding walls;

b. Install hanger: In the joints of cast-in-place or precast slabs, set embedded parts or arrange φ10 expansion bolts according to the design requirements, with a spacing of no more than 1m, fix iron parts, and weld φ8 threaded steel bars. The hanger should be straight and have sufficient bearing capacity. When the embedded hanger needs to be extended, it must be overlapped and welded firmly, and the weld should be uniform and full;

c. Install main keel: According to the design, select the main keel ceiling spacing, with a spacing of no more than 1m. For large rooms, the middle part should be arched. The arch height of metal keels should not be less than 1/200 of the short span of the room. The position and elevation of the main keel should be corrected in time after installation;

d. Install secondary keel and cross brace small keel: According to the needs of board layout, prepare qualified secondary keels in advance, and connect their two ends to the full-length secondary keels with connectors. The gap between the cross brace keel and the full-length secondary keel of Minglong series should not be greater than 1 mm;

e. Correct the position and levelness of main and secondary keels comprehensively. The connectors should be staggered for installation. Minglong keels should have no obvious bending by visual inspection. The misalignment deviation of the butt joint of full-length secondary keels should not exceed 2mm. After correction, all hangers and connectors of keels should be tightened.

f. Calcium silicate board installation: No other materials should be placed on the calcium silicate board to prevent the board from being compressed and deformed. It is not suitable to install when the humidity in the room is high. When installing, make sure that the arrow direction and white line direction on the back of calcium silicate board are consistent to ensure the integrity of patterns and designs; use shelving method for installation, and leave installation joints for boards.

Interior partition board and ceiling board for buildings such as office, mall, hotel, hospital, stadium, school, station, etc.: Interior partition board for carriages, offshore buildings, ships, etc. that have fireproof, heat insulation and moisture-proof requirements.